Pompa Haskel The Engine of Precision and Power in Modern Industries

In the intricate world of high-pressure systems, pompa Haskel stands as a trusted name, a benchmark of engineering excellence that has transformed industries requiring precision, power, and reliability. From aerospace applications to oil and gas operations, Haskel pumps exemplify innovation where it matters most: in environments demanding uncompromising performance.

For decades, industries have leaned on this robust technology, quietly shaping outcomes in energy production, manufacturing, and industrial testing—making Haskel pumps far more than machines, but instruments of measurable progress.

What is a Pompa Haskel?

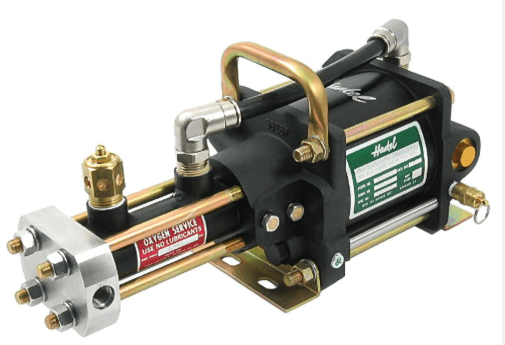

At its core, a pompa Haskel is a high-pressure, air-driven pump designed to amplify and control pressure in industrial applications. Unlike traditional electric pumps, Haskel pumps operate without the need for external power sources, relying instead on compressed air or gas for operation.

This unique design allows for:

- Safer operations in hazardous or volatile environments.

- Unparalleled precision in pressure control.

- High durability, even under extreme conditions.

Haskel pumps are used globally in industries where precision and safety are paramount, from chemical processing plants to aircraft hydraulic systems.

Applications of Pompa Haskel Across Industries

The versatility of Haskel pumps has made them indispensable across a wide range of sectors. Here’s how they play a critical role in different industries:

- Oil and Gas

- Used for chemical injection, pipeline testing, and gas boosting.

- Key to ensuring safe operations in offshore drilling and refineries.

- Global oil industry data shows that reliable high-pressure systems like Haskel can reduce equipment downtime by 30%.

- Aerospace

- Integral in ground support equipment for hydraulic testing and fuel transfer.

- Ensures precision and reliability in aircraft maintenance and operations.

- Manufacturing and Industrial Testing

- Used for leak testing, hydraulic presses, and pressure system validation.

- Reduces failure rates in machinery, with precision measurements improving operational efficiency.

- Energy Sector

- Plays a pivotal role in hydrogen compression for fuel cells.

- Facilitates the development of clean energy solutions. Global hydrogen markets are expected to grow to $201 billion by 2025, further underscoring Haskel’s relevance.

- Automotive and Defence

- Supports component testing for safety-critical applications, such as brakes and hydraulic systems.

- High-pressure equipment ensures operational precision under rigorous conditions.

Key Features of Pompa Haskel That Set It Apart

When it comes to high-pressure systems, not all pumps are created equal. The standout features of Haskel pumps include:

- Air-Driven Mechanism

- No electrical components, making it suitable for hazardous or explosive environments.

- High Efficiency and Low Maintenance

- Designed for durability, with minimal wear and tear even in continuous operation.

- Maintenance cycles are longer compared to conventional systems.

- Precise Pressure Control

- Handles pressures up to 100,000 psi, offering unparalleled accuracy.

- Supports adjustable flow rates without compromising on performance.

- Compact and Lightweight

- Easy to integrate into existing systems, reducing installation complexity.

- Global Reliability

- With decades of proven performance, Haskel pumps are trusted in over 100 countries worldwide, a testament to their engineering quality.

Why Haskel Pumps Are a Sustainable Choice

In an era where sustainability matters, Haskel pumps align with industry goals for energy efficiency and reduced environmental impact:

- No Electricity Dependency: Their air-driven design reduces energy consumption.

- Lower Carbon Emissions: Efficient operation translates to reduced waste and emissions.

- Extended Lifespan: Built to last, Haskel pumps reduce equipment turnover and waste in industrial settings.

For industries adopting green technologies, particularly hydrogen fuel production, Haskel’s role in hydrogen compression is pivotal.

The Global Trust in Haskel Pumps

Numbers tell a story of trust and reliability:

- Haskel has over 75 years of experience designing high-pressure systems.

- Its products are deployed in 100+ countries across critical industries.

- Pumps like the Haskel air-driven model boast a 99% operational uptime, ensuring minimal disruptions.

This track record has cemented Haskel as the gold standard in high-pressure pumping solutions worldwide.

How to Choose the Right Pompa Haskel for Your Needs

With a wide variety of Haskel pumps available, selecting the right model depends on your specific requirements. Consider these factors:

- Pressure Requirements: Determine the maximum pressure your application demands. Haskel pumps can handle pressures from 1,000 to 100,000 psi.

- Flow Rate: Identify the volume of fluid or gas to be moved per minute.

- Application Type: Whether you need hydraulic testing, gas boosting, or chemical injection.

- Operating Environment: For hazardous or explosion-prone areas, Haskel’s air-driven models are ideal.

Consulting with authorised Haskel distributors ensures you get tailored solutions for your industrial needs.

Maintaining Your Haskel Pump for Longevity

While Haskel pumps are designed for durability, proper maintenance ensures optimal performance:

- Regular Inspections: Check seals, valves, and pressure components periodically.

- Monitor Air Supply: Ensure clean, dry compressed air for efficient operation.

- Replace Wear Parts: Use genuine Haskel parts to maintain reliability.

- Professional Servicing: Schedule annual servicing to identify potential issues early.

By following these practices, you can extend the lifespan of your Haskel pump and maintain peak efficiency.

Final Thoughts: The Power of Precision with Pompa Haskel

In a world that demands reliability, efficiency, and sustainability, pompa Haskel emerges as an indispensable solution across industries. Its air-driven precision, robust performance, and unmatched durability make it a cornerstone for applications ranging from energy to aerospace.

For businesses and industries striving to reduce downtime, enhance safety, and meet sustainability targets, Haskel pumps offer a future-proof investment. Whether you’re testing a critical component, boosting gas pressure, or driving clean energy innovations, the pompa Haskel remains a beacon of engineering excellence that delivers results, every time.